Product Description

Product Description

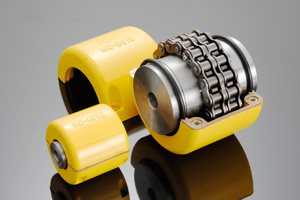

We can supply Jaw coupling, PF coupling, MC/MCT coupling, KX/KXT coupling, F-FLEXBLE coupling, HRC coupling, Chain coupling, NM coupling, MH coupling, Adjustble spacer coupling, Fenaflex coupling, Shaft coupling, Rigid coupling, Pin coupling.

With top quality, competitive price and prompt delivery, welcome your inquiry, thank you!

Detailed Photos

Our Advantages

| WHY CHOOSE US |

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years.

| FAQ |

| Q1: What’s your average lead time? A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate. Q2: Is your price better than your competitors given the same quality? Q4: Can we inspect the goods before shipment? Q5: What kind of payment method is acceptable for your mill? Q6: What if I have any other questions? |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Efficient Power Transmission and Low Maintenance of Roller Chain Couplings

Roller chain couplings offer efficient power transmission and low maintenance due to their unique design and construction:

- High Torque Capacity: Roller chain couplings are capable of transmitting high torque between the driving and driven shafts, making them suitable for heavy-duty applications.

- Reduced Power Loss: The flexible and rugged nature of roller chain couplings helps minimize power loss during torque transmission, ensuring energy efficiency in the system.

- Shock Absorption: Roller chain couplings can absorb shocks and vibrations, protecting connected machinery and components from damage and wear.

- Misalignment Tolerance: They can accommodate both angular and parallel misalignments, reducing stress on the shafts and extending the equipment’s life.

- Simple and Reliable Design: Roller chain couplings have a simple design with fewer moving parts, leading to low maintenance requirements and reduced downtime.

- Easy Installation: Their easy installation process allows for quick setup, minimizing installation time and associated costs.

- Durability and Longevity: Roller chain couplings are made from robust materials such as steel, ensuring durability and longevity even in harsh operating conditions.

- Cost-Effectiveness: Due to their long service life and low maintenance needs, roller chain couplings offer a cost-effective solution for power transmission applications.

Overall, roller chain couplings provide reliable and efficient power transmission while requiring minimal maintenance, making them a preferred choice in various industries where continuous operation and reduced downtime are essential.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

How to Select the Right Roller Chain Coupling for Specific Machinery or Equipment?

Selecting the right roller chain coupling for specific machinery or equipment involves considering several important factors. Here’s a step-by-step guide:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the driving and driven shafts. This will help you choose a coupling with the appropriate torque capacity for your application.

- Speed: Consider the operating speed of the machinery. Higher speeds may require special high-speed roller chain couplings designed to handle the centrifugal forces.

- Misalignment: Evaluate the degree of misalignment between the shafts. Different roller chain couplings have varying misalignment capabilities, so choose one that can accommodate the misalignment in your application.

- Space Constraints: Measure the available space for the coupling. Some roller chain couplings are compact and may be suitable for applications with limited space.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose a coupling material and finish that can withstand the environmental conditions.

- Load Characteristics: Assess the nature of the loads and any shock or vibration present in the system. For heavy-duty or shock-loaded applications, consider using heavy-duty roller chain couplings.

- Alignment Maintenance: Evaluate the ease of alignment maintenance. Some couplings may require more frequent checks and adjustments to maintain proper alignment.

- Backlash: Determine the level of backlash permissible in the application. Certain couplings may introduce minimal backlash, which is critical in precision systems.

- Cost: Consider the overall cost, including the initial purchase price and long-term maintenance expenses. Opt for a roller chain coupling that provides the best value for your specific needs.

By carefully considering these factors, engineers and designers can identify the most suitable roller chain coupling that ensures reliable and efficient power transmission for their machinery or equipment.

editor by CX 2024-03-07