Product Description

Product Description

COUPLINGS

| HRC | FCL | Chain coupling | GE | L | NM | MH | Torque limiter |

| HRC 70B | FCL90 | KC4012 | GE14 | L050 | NM50 | MH45 | TL250-2 |

| HRC 70F | FCL100 | KC4014 | GE19 | L070 | NM67 | MH55 | TL250-1 |

| HRC 70H | FCL112 | KC4016 | GE24 | L075 | NM82 | MH65 | TL350-2 |

| HRC 90B | FCL125 | KC5014 | GE28 | L090 | NM97 | MH80 | TL350-1 |

| HRC 90F | FCL140 | KC5016 | GE38 | L095 | NM112 | MH90 | TL500-2 |

| HRC 90H | FCL160 | KC6018 | GE42 | L099 | NM128 | MH115 | TL500-1 |

| HRC 110B | FCL180 | KC6571 | GE48 | L100 | NM148 | MH130 | TL700-2 |

| HRC 110F | FCL200 | KC6571 | GE55 | L110 | NM168 | MH145 | TL700-1 |

| HRC 110H | FCL224 | KC8018 | GE65 | L150 | NM194 | MH175 | |

| HRC 130B | FCL250 | KC8571 | GE75 | L190 | NM214 | MH200 | |

| HRC 130F | FCL280 | KC8571 | GE90 | L225 | |||

| HRC 130H | FCL315 | KC1571 | |||||

| HRC 150B | FCL355 | KC12018 | |||||

| HRC 150F | FCL400 | KC12571 | |||||

| HRC 150H | FCL450 | ||||||

| HRC 180B | FCL560 | ||||||

| HRC 180F | FCL630 | ||||||

| HRC 180H | |||||||

| HRC 230B | |||||||

| HRC 230F | |||||||

| HRC 230H | |||||||

| HRC 280B | |||||||

| HRC 280F | |||||||

| HRC 280H |

Catalogue

Workshop

Lots of coupling in stock

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: 10-20 days.

2.Production Lead-times: 30-45 days after order confirmed.

Q3: What is your advantages?

1. The most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

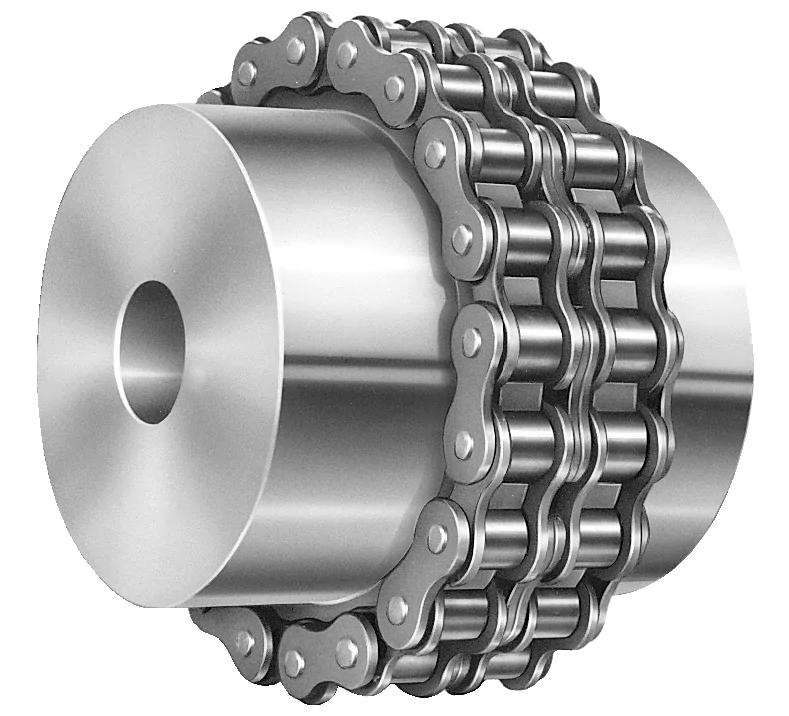

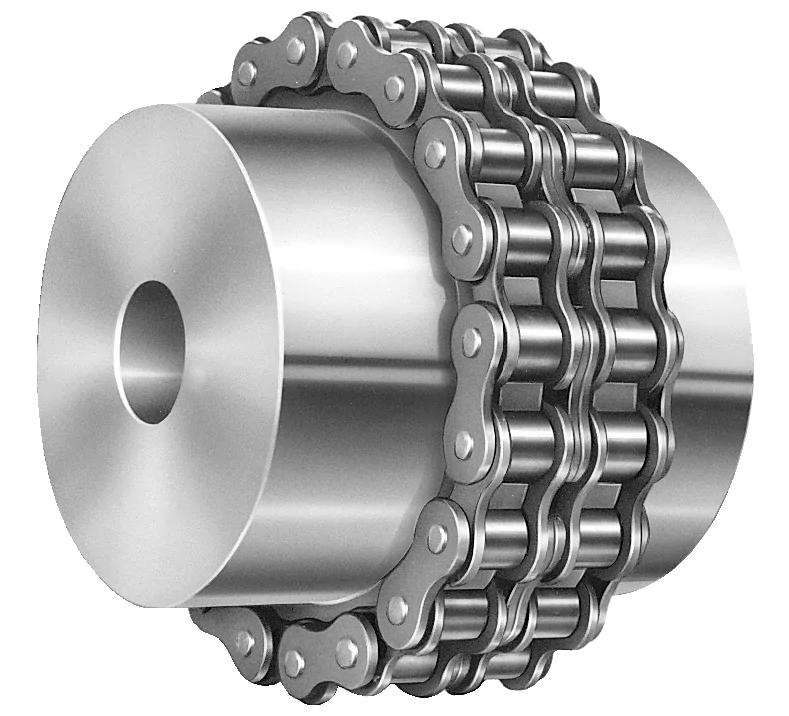

Standard Sizes and Specifications of Roller Chain Couplings

Roller chain couplings come in various sizes and specifications to accommodate a wide range of mechanical power transmission applications. The standard sizes and specifications of roller chain couplings typically include:

- Chain Size: Roller chain couplings are available in different chain sizes, such as 40, 50, 60, 80, 100, etc. The chain size indicates the pitch of the roller chain used in the coupling.

- Torque Capacity: The torque capacity of a roller chain coupling varies based on its size and design. Manufacturers provide torque ratings that specify the maximum amount of torque the coupling can handle without failure.

- Speed Rating: Roller chain couplings have a maximum speed rating, which indicates the highest rotational speed at which the coupling can operate safely and efficiently.

- Material: Roller chain couplings are commonly made from materials such as carbon steel, stainless steel, or nickel-plated steel, providing different levels of strength, corrosion resistance, and durability.

- Hub Type: Roller chain couplings may come with different hub types, such as pilot bore hubs or taper bore hubs, to suit various shaft connections.

- Number of Teeth: Some roller chain couplings have specific tooth configurations that can affect their performance and backlash characteristics.

- Misalignment Capacity: Manufacturers specify the maximum allowable misalignment (angular and parallel) that the coupling can accommodate to ensure reliable operation.

It is essential to refer to the manufacturer’s catalogs or product specifications to determine the exact sizes and specifications available for specific roller chain couplings. Selecting the right size and specifications depends on the application’s requirements, including torque, speed, misalignment, and environmental conditions.

Maintenance Requirements for Roller Chain Couplings

To ensure the optimal performance and longevity of roller chain couplings, regular maintenance is essential. Here are some key maintenance requirements:

- Lubrication: Regularly lubricate the roller chain and sprockets to reduce friction and wear. Use the appropriate lubricant recommended by the coupling manufacturer.

- Inspections: Periodically inspect the coupling for signs of wear, misalignment, or damage. Look for elongation or wear of the roller chain, damaged sprocket teeth, or any signs of excessive vibration.

- Tightening: Check and ensure that all fasteners, such as bolts and set screws, are properly tightened to the manufacturer’s recommended torque specifications.

- Alignment: Maintain proper alignment between the driving and driven shafts to prevent undue stress on the coupling components.

- Cleanliness: Keep the coupling and surrounding area clean and free from debris or contaminants that could interfere with its operation.

- Temperature: Avoid operating the coupling beyond its recommended temperature limits, as excessive heat can lead to premature failure.

- Replacement: Replace any worn or damaged components promptly to prevent further damage to the coupling or connected equipment.

Regular maintenance not only ensures the coupling’s optimal performance but also helps identify potential issues early, allowing for timely repairs or replacements. It is crucial to follow the manufacturer’s maintenance guidelines and schedule to ensure the coupling’s reliability and prevent unexpected failures that could disrupt operations and lead to costly downtime.

What are the Different Types of Roller Chain Couplings Used in Various Industrial Applications?

Roller chain couplings come in several variations to suit different industrial applications. The main types of roller chain couplings include:

- Standard Roller Chain Couplings: These are the most common type of roller chain couplings, featuring two sprockets of the same size connected by a standard roller chain. They are used in general power transmission applications and are suitable for moderate torque requirements.

- Heavy-Duty Roller Chain Couplings: As the name suggests, these couplings are designed for heavy-duty applications that require higher torque capacity. They typically have larger and stronger sprockets and chains to handle increased loads.

- Double Roller Chain Couplings: This type of coupling includes two roller chains side by side on each sprocket. It offers higher torque transmission capabilities and increased redundancy for critical applications.

- Idler Roller Chain Couplings: In this design, an idler sprocket is added between the driving and driven sprockets. It helps to reduce the impact of shock loads and misalignment on the coupling.

- Spacer Roller Chain Couplings: These couplings have a spacer between the two sprockets, allowing for larger axial misalignment while maintaining torque transmission.

The choice of the roller chain coupling type depends on the specific requirements of the application, including torque, speed, misalignment, and environmental factors. Engineers and designers need to select the appropriate type of coupling to ensure reliable and efficient power transmission in their industrial machinery.

editor by CX 2024-04-19