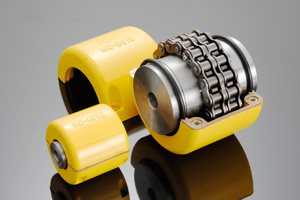

Product Description

| Product Name | Roller Chain coupling |

| Model NO. | KC3012 KC4012 KC4014 KC4016 KC5014 KC5016 KC5018 KC6018 KC6571 KC6571 KC8018 KC8571 KC8571 KC1571 KC12018 KC12571 |

| Chain Type | 06B-2×12 40-2×12 40-2×14 40-2×16 50-2×14 50-2×16 50-2×18 60-2×18 60-2×20 60-2×22 100-2×20 100-2×18 100-2×22 |

| Min. Bore Diameter | 12mm-35mm, customized |

| Max. Bore Diameter | 16mm-140mm,customized |

| Weight | 0.4kg-72.0kg |

| Material | Stainless Steel,Carbon Steel,Aluminum Sleeve |

| Cover Dimensions | 63mm-357mm, customized |

Features

The chain coupling is composed a duplex roller chain and 2 sprockets.The function of connection and datachment is done by the joint of chain.It has the characteristics of simplicity,high efficiency,easy-on and easy-off and nice out-looking.It also have aluminum cover to prevent dust and protect the lubricant in order to extend the life of chain coupling.

Chain couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

The chain coupling has the advantages of simple structure (consisting of 4 parts), convenient installation and disassembly, 2 shafts which are joined without moving during disassembly, compact size, light weight, compensation ability, low installation accuracy, reliable operation, long life and low cost.

| Packing&Shipping | |

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate. |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

About MIGHTY

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

FAQ

Q: Are you manufacturer or trading company?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Reducing Vibrations and Ensuring Smooth Operation with Roller Chain Couplings

Roller chain couplings are designed to provide a flexible and torsionally soft connection between shafts, which helps in reducing vibrations and ensuring smooth operation in mechanical power transmission systems. Here’s how roller chain couplings contribute to achieving these benefits:

- Shock Absorption: Roller chain couplings have the ability to absorb and dampen shock loads that may occur due to sudden starts, stops, or changes in the load. This feature prevents the transmission of these shocks to connected equipment, reducing vibrations and protecting the system from mechanical damage.

- Torsional Flexibility: The flexibility of roller chain couplings allows for slight misalignments between shafts. This capability helps in accommodating minor misalignments, which might otherwise lead to increased vibrations and noise in rigid coupling systems.

- Uniform Load Distribution: Roller chain couplings distribute the transmitted torque uniformly along the chain, reducing stress concentration on specific components. This even distribution of load helps in maintaining smooth operation and prolonging the life of the coupling.

- Damping Properties: The material properties of roller chain couplings, such as the use of elastomeric or plastic elements in some designs, provide inherent damping characteristics. This damping helps in absorbing vibrations and preventing resonance, ensuring stable and smooth operation.

- Reduced Backlash: Roller chain couplings exhibit minimal backlash due to the precise fit of the chain’s teeth with the sprockets. This feature is beneficial in applications that require accurate positioning and motion control.

By reducing vibrations and ensuring smooth operation, roller chain couplings contribute to improved overall system performance, reduced wear and tear on components, and enhanced reliability in various industrial applications.

Working Principle of Roller Chain Coupling and Its Advantages

A roller chain coupling works on the principle of transferring torque between two shafts using a roller chain wrapped around sprockets on each shaft. The sprockets are connected by the roller chain, and when one sprocket rotates, it drives the other sprocket, transmitting the torque from one shaft to the other.

The advantages of roller chain couplings over other coupling types include:

- High Torque Capacity: Roller chain couplings can handle high torque loads, making them suitable for heavy-duty industrial applications.

- Compact Design: The compact and simple design of roller chain couplings allows for easy installation in tight spaces and restricted environments.

- Misalignment Tolerance: Roller chain couplings can accommodate angular, parallel, and axial misalignments between the shafts, reducing the need for precise alignment during installation.

- Shock Absorption: The inherent flexibility of the roller chain allows it to absorb shocks and dampen vibrations, protecting connected equipment from sudden loads and impacts.

- Cost-Effective: Roller chain couplings are generally cost-effective compared to other coupling types, providing an economical solution for power transmission needs.

- Wide Application Range: Roller chain couplings are used in various industries, including manufacturing, agriculture, construction, and material handling, due to their versatility and reliable performance.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain and require minimal lubrication to keep the chain running smoothly.

- Long Service Life: When properly installed and maintained, roller chain couplings offer a long service life, contributing to the overall efficiency and reliability of mechanical systems.

Overall, the working principle and advantages of roller chain couplings make them a popular choice for transmitting torque between shafts in diverse industrial applications.

editor by CX 2024-04-23