Product Description

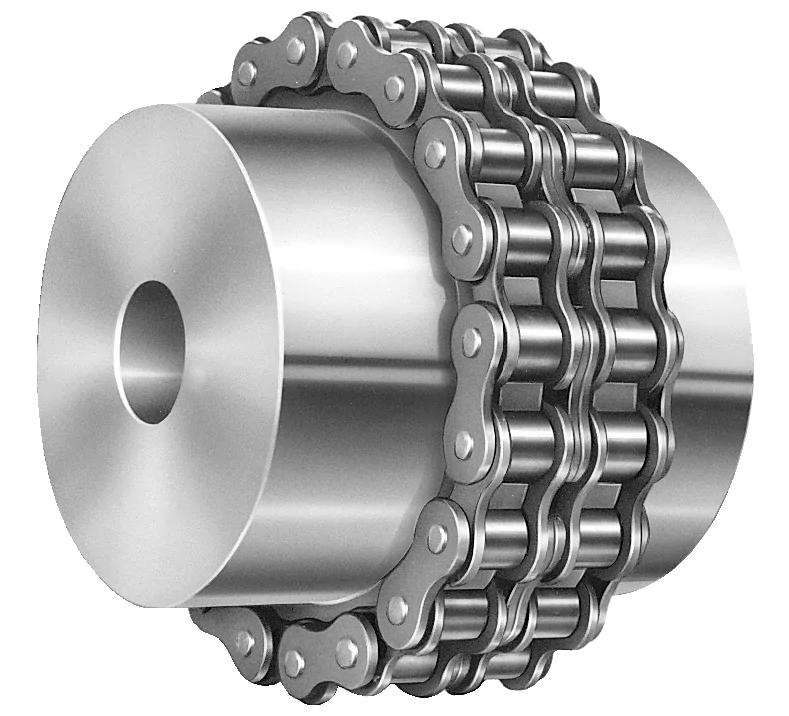

High torque and reliable KC coupling roller chain couplings with a chain and a pair of sprockets

Description:

The chain coupling consists of two-strand roller chains, 2 sprockets and AL-Alloy cover, features simple and compact structure, and high flexibility, power transmission capability and durability.

What’s more ,the chain coupling allows simple connection/disconnection, and the use of the housing enhances safety and durability.

Advantages:

1. Material: C45 steel, Aluminum, Rubber and plastic etc.

2. High efficiency in transmission

3. Finishing: blacken, phosphate-coat, and oxidation.

4. Different models suitable for your different demands

5. Application in wide range of environment.

6. Quick and easy mounting and disassembly.

7. Resistant to oil and electrical insulation.

8. Identical clockwise and anticlockwise rotational characteristics.

9. Small dimension, low weight, high transmitted torque.

10. It has good performance.

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Finding Reputable Suppliers or Manufacturers of Roller Chain Couplings

When looking for reputable suppliers or manufacturers of roller chain couplings for your specific power transmission needs, consider the following options:

- Industrial Trade Shows: Attend industrial trade shows and exhibitions related to power transmission and machinery. These events often feature leading manufacturers and suppliers showcasing their products.

- Online Directories: Utilize online directories and platforms that list suppliers and manufacturers of industrial equipment. Look for well-established companies with positive customer reviews and ratings.

- Industry Associations: Contact industry associations related to power transmission or mechanical engineering. They can provide recommendations for reliable coupling manufacturers and suppliers.

- Referrals and Recommendations: Ask for referrals and recommendations from colleagues, industry experts, or other businesses using similar equipment. Word-of-mouth recommendations can help you find trusted suppliers.

- Supplier Websites: Visit the websites of potential suppliers to learn more about their product offerings, certifications, and customer support services.

- Customer Support: Look for manufacturers or suppliers with excellent customer support to assist with technical inquiries, product selection, and after-sales service.

- Customization: If you have unique requirements, consider working with a manufacturer that offers customization options to tailor the coupling to your specific needs.

By researching and comparing different suppliers, you can find a reputable and reliable source for roller chain couplings that meets your power transmission needs.

Handling Angular and Parallel Misalignments with Roller Chain Couplings

Yes, roller chain couplings are designed to accommodate both angular and parallel misalignments simultaneously. These couplings use a flexible roller chain to transmit torque between the driving and driven shafts, allowing for some degree of misalignment without causing undue stress on the coupling or connected equipment.

The roller chain’s flexible nature enables it to bend and twist slightly, accommodating small angular misalignments between the shafts. Additionally, the design of the sprockets and chain links allows for some axial movement, which addresses parallel misalignments.

It is important to note that while roller chain couplings can handle moderate misalignments, excessive misalignment should be avoided to prevent premature wear and potential coupling failure. Regular maintenance and alignment checks are crucial to ensure the coupling operates within its design limits and delivers reliable performance.

What are the Different Types of Roller Chain Couplings Used in Various Industrial Applications?

Roller chain couplings come in several variations to suit different industrial applications. The main types of roller chain couplings include:

- Standard Roller Chain Couplings: These are the most common type of roller chain couplings, featuring two sprockets of the same size connected by a standard roller chain. They are used in general power transmission applications and are suitable for moderate torque requirements.

- Heavy-Duty Roller Chain Couplings: As the name suggests, these couplings are designed for heavy-duty applications that require higher torque capacity. They typically have larger and stronger sprockets and chains to handle increased loads.

- Double Roller Chain Couplings: This type of coupling includes two roller chains side by side on each sprocket. It offers higher torque transmission capabilities and increased redundancy for critical applications.

- Idler Roller Chain Couplings: In this design, an idler sprocket is added between the driving and driven sprockets. It helps to reduce the impact of shock loads and misalignment on the coupling.

- Spacer Roller Chain Couplings: These couplings have a spacer between the two sprockets, allowing for larger axial misalignment while maintaining torque transmission.

The choice of the roller chain coupling type depends on the specific requirements of the application, including torque, speed, misalignment, and environmental factors. Engineers and designers need to select the appropriate type of coupling to ensure reliable and efficient power transmission in their industrial machinery.

editor by CX 2024-04-29