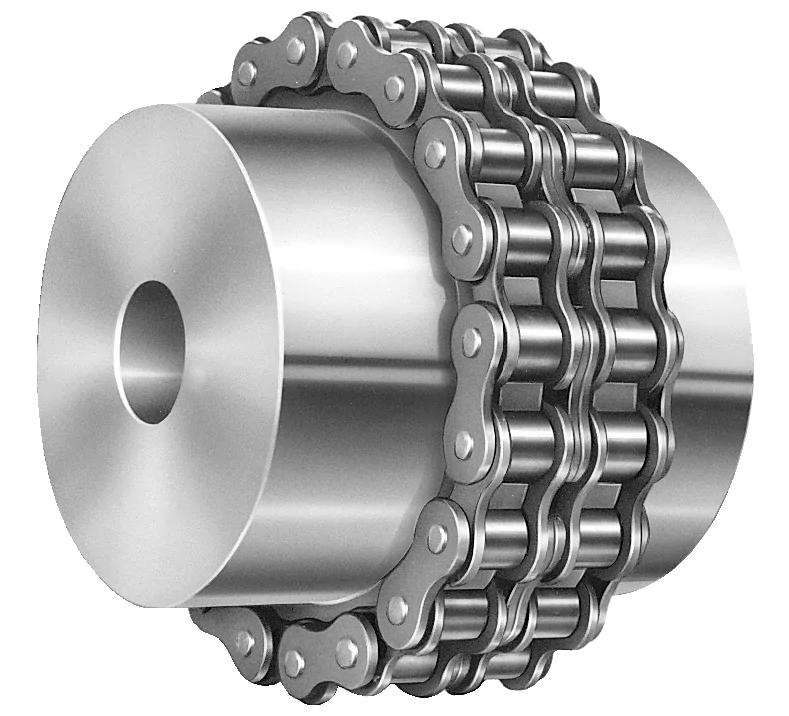

Product Description

chain coupling, roller chain with sprocket assembly for transmission system.

Chain couplings are suitable for the elastic transmission of rotating components over a wider speed range.

the couplings consist of 2 pre-drilled sprockets with the same number of teeth and a double roller chain DIN8171 with a straight spring lock

the simple opening of these couplings allows quick assembly and disassembly by simply loosening the connecting chain

all in one, the product offers an optimal price / ratio for numerous applications.

on request and depending on the application, the chain couplings can be supplied with hardened teeth as well as with a bore with an adjusting screw cap per wheel

Technical data list,

| Coupling No | Chain type | Teeth Number | Dm | A | E | L | H | d |

| YC0614 | 06B-2 | 14/14 | 31 | 25 | 51 | 55 | 16.6 | 8 |

| YC0618 | 06B-2 | 18/18 | 43 | 28 | 63 | 61 | 16.6 | 10 |

| YC571 | 08B-2 | 14/14 | 41 | 28 | 68.9 | 62.7 | 22 | 10 |

| YC 0571 | 08B-2 | 18/18 | 56 | 28 | 85 | 62.7 | 22 | 12 |

| YC1018 | 10B-2 | 18/18 | 70 | 30 | 106.2 | 67.5 | 26 | 14 |

| YC1218 | 12B-2 | 18/18 | 80 | 35 | 125.8 | 78.4 | 28 | 16 |

| YC1224 | 12B-2 | 24/24 | 90 | 40 | 162.1 | 88.4 | 28 | 20 |

| YC1618 | 16B-2 | 18/18 | 100 | 45 | 167.3 | 105.7 | 47 | 20 |

| YC1624 | 16B-2 | 24/24 | 110 | 50 | 215.6 | 115.7 | 47 | 20 |

Products picture,

Packing picture,

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in single color box. If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance. Other payments terms, pls negotiate with us in advance, we can discuss.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 30 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.We welcome sample order.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Retrofitting Roller Chain Couplings for Improved Performance

Yes, roller chain couplings can be retrofitted into existing systems to improve performance and enhance power transmission capabilities. Retrofitting is a cost-effective way to upgrade the coupling system without the need for significant modifications to the existing machinery.

When considering a retrofit with roller chain couplings, it is essential to ensure that the new couplings are compatible with the existing shaft sizes and operating conditions. The dimensions of the roller chain couplings should match the space available in the system, and the torque and speed ratings should meet or exceed the requirements of the application.

The advantages of retrofitting with roller chain couplings include:

- Increased Torque Capacity: Roller chain couplings can handle higher torque loads compared to some other coupling types, providing improved power transmission capabilities.

- Better Misalignment Tolerance: Roller chain couplings can accommodate both angular and parallel misalignments, reducing stress on the connected equipment and extending its service life.

- Shock Load Absorption: The flexibility of roller chain couplings allows them to absorb shock loads, protecting the drivetrain and other mechanical components from sudden impacts.

- Reduced Downtime: Retrofitting can be a quick and straightforward process, minimizing downtime during the upgrade.

Before proceeding with the retrofit, it is essential to consult with coupling manufacturers or engineering experts to ensure the proper selection and installation of roller chain couplings. Additionally, regular maintenance and inspections are crucial to ensure continued optimal performance and reliability of the retrofitted coupling system.

Materials Used in Manufacturing Roller Chain Couplings

Roller chain couplings are typically constructed from high-quality materials to ensure durability and reliable performance. The most common materials used in their manufacturing include:

- Steel: Steel is a popular choice for roller chain couplings due to its excellent strength and resistance to wear. It can handle high torque and speed requirements, making it suitable for a wide range of industrial applications.

- Stainless Steel: Stainless steel is used when corrosion resistance is required. It is often employed in industries where the coupling is exposed to moisture, chemicals, or harsh environmental conditions.

- Cast Iron: Cast iron is known for its robustness and excellent heat dissipation properties. It is commonly used in applications where shock absorption and reduced vibrations are essential.

- Aluminum: Aluminum is a lightweight material that offers good strength-to-weight ratio. It is commonly used in applications where reducing the overall weight of the system is critical.

- Nickel-Plated: Nickel-plated roller chain couplings provide enhanced corrosion resistance, making them suitable for applications in challenging environments.

When selecting a roller chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, environment, and potential exposure to corrosive substances. Choosing the right material ensures the coupling’s longevity and efficient power transmission in the intended operating conditions.

What are the Different Types of Roller Chain Couplings Used in Various Industrial Applications?

Roller chain couplings come in several variations to suit different industrial applications. The main types of roller chain couplings include:

- Standard Roller Chain Couplings: These are the most common type of roller chain couplings, featuring two sprockets of the same size connected by a standard roller chain. They are used in general power transmission applications and are suitable for moderate torque requirements.

- Heavy-Duty Roller Chain Couplings: As the name suggests, these couplings are designed for heavy-duty applications that require higher torque capacity. They typically have larger and stronger sprockets and chains to handle increased loads.

- Double Roller Chain Couplings: This type of coupling includes two roller chains side by side on each sprocket. It offers higher torque transmission capabilities and increased redundancy for critical applications.

- Idler Roller Chain Couplings: In this design, an idler sprocket is added between the driving and driven sprockets. It helps to reduce the impact of shock loads and misalignment on the coupling.

- Spacer Roller Chain Couplings: These couplings have a spacer between the two sprockets, allowing for larger axial misalignment while maintaining torque transmission.

The choice of the roller chain coupling type depends on the specific requirements of the application, including torque, speed, misalignment, and environmental factors. Engineers and designers need to select the appropriate type of coupling to ensure reliable and efficient power transmission in their industrial machinery.

editor by CX 2024-04-08