Product Description

FAQ

Q:Is your company a trading company or a manufacturer?

A: We have our own factory.

Q:How long does the lead time take?

A: If the goods are in stock, it is generally 1-2 days; if the goods are not in stock, it is 5-10 days, depending on the quantity.

Q: Can I order shaft bore couplings that are not listed in the catalog?)(Additional machining service for coupling shaft hole

A:Of course.In addition, the recommended dimensional tolerance for the applicable shaft diameter is H7.

Q: How to handle when the received parts are of poor quality?

A:If there is any non-conformity of the product, please contact us immediately, we will check the problem in the first time, and rework or repair.

Q: Why choose XingHe Precision Transmission ?

A:As a professional manufacturer of coupling , we possess a skillful team of workers and designers To provide our customers with first-class services.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

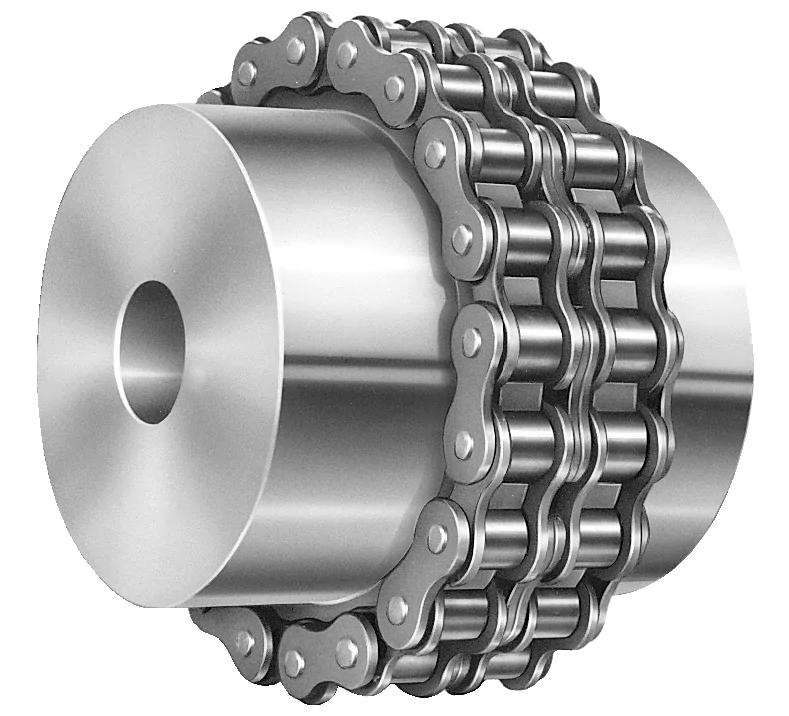

Standard Sizes and Specifications of Roller Chain Couplings

Roller chain couplings come in various sizes and specifications to accommodate a wide range of mechanical power transmission applications. The standard sizes and specifications of roller chain couplings typically include:

- Chain Size: Roller chain couplings are available in different chain sizes, such as 40, 50, 60, 80, 100, etc. The chain size indicates the pitch of the roller chain used in the coupling.

- Torque Capacity: The torque capacity of a roller chain coupling varies based on its size and design. Manufacturers provide torque ratings that specify the maximum amount of torque the coupling can handle without failure.

- Speed Rating: Roller chain couplings have a maximum speed rating, which indicates the highest rotational speed at which the coupling can operate safely and efficiently.

- Material: Roller chain couplings are commonly made from materials such as carbon steel, stainless steel, or nickel-plated steel, providing different levels of strength, corrosion resistance, and durability.

- Hub Type: Roller chain couplings may come with different hub types, such as pilot bore hubs or taper bore hubs, to suit various shaft connections.

- Number of Teeth: Some roller chain couplings have specific tooth configurations that can affect their performance and backlash characteristics.

- Misalignment Capacity: Manufacturers specify the maximum allowable misalignment (angular and parallel) that the coupling can accommodate to ensure reliable operation.

It is essential to refer to the manufacturer’s catalogs or product specifications to determine the exact sizes and specifications available for specific roller chain couplings. Selecting the right size and specifications depends on the application’s requirements, including torque, speed, misalignment, and environmental conditions.

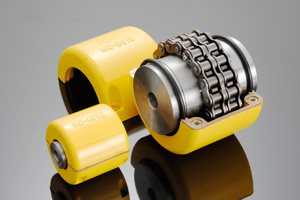

Handling Angular and Parallel Misalignments with Roller Chain Couplings

Yes, roller chain couplings are designed to accommodate both angular and parallel misalignments simultaneously. These couplings use a flexible roller chain to transmit torque between the driving and driven shafts, allowing for some degree of misalignment without causing undue stress on the coupling or connected equipment.

The roller chain’s flexible nature enables it to bend and twist slightly, accommodating small angular misalignments between the shafts. Additionally, the design of the sprockets and chain links allows for some axial movement, which addresses parallel misalignments.

It is important to note that while roller chain couplings can handle moderate misalignments, excessive misalignment should be avoided to prevent premature wear and potential coupling failure. Regular maintenance and alignment checks are crucial to ensure the coupling operates within its design limits and delivers reliable performance.

How to Select the Right Roller Chain Coupling for Specific Machinery or Equipment?

Selecting the right roller chain coupling for specific machinery or equipment involves considering several important factors. Here’s a step-by-step guide:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the driving and driven shafts. This will help you choose a coupling with the appropriate torque capacity for your application.

- Speed: Consider the operating speed of the machinery. Higher speeds may require special high-speed roller chain couplings designed to handle the centrifugal forces.

- Misalignment: Evaluate the degree of misalignment between the shafts. Different roller chain couplings have varying misalignment capabilities, so choose one that can accommodate the misalignment in your application.

- Space Constraints: Measure the available space for the coupling. Some roller chain couplings are compact and may be suitable for applications with limited space.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose a coupling material and finish that can withstand the environmental conditions.

- Load Characteristics: Assess the nature of the loads and any shock or vibration present in the system. For heavy-duty or shock-loaded applications, consider using heavy-duty roller chain couplings.

- Alignment Maintenance: Evaluate the ease of alignment maintenance. Some couplings may require more frequent checks and adjustments to maintain proper alignment.

- Backlash: Determine the level of backlash permissible in the application. Certain couplings may introduce minimal backlash, which is critical in precision systems.

- Cost: Consider the overall cost, including the initial purchase price and long-term maintenance expenses. Opt for a roller chain coupling that provides the best value for your specific needs.

By carefully considering these factors, engineers and designers can identify the most suitable roller chain coupling that ensures reliable and efficient power transmission for their machinery or equipment.

editor by CX 2024-02-11