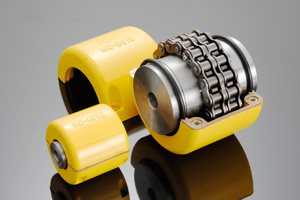

Product Description

| Product Name | Roller Chain coupling |

| Model NO. | KC3012 KC4012 KC4014 KC4016 KC5014 KC5016 KC5018 KC6018 KC6571 KC6571 KC8018 KC8571 KC8571 KC1571 KC12018 KC12571 |

| Chain Type | 06B-2×12 40-2×12 40-2×14 40-2×16 50-2×14 50-2×16 50-2×18 60-2×18 60-2×20 60-2×22 100-2×20 100-2×18 100-2×22 |

| Min. Bore Diameter | 12mm-35mm, customized |

| Max. Bore Diameter | 16mm-140mm,customized |

| Weight | 0.4kg-72.0kg |

| Material | Stainless Steel,Carbon Steel,Aluminum Sleeve |

| Cover Dimensions | 63mm-357mm, customized |

Features

The chain coupling is composed a duplex roller chain and 2 sprockets.The function of connection and datachment is done by the joint of chain.It has the characteristics of simplicity,high efficiency,easy-on and easy-off and nice out-looking.It also have aluminum cover to prevent dust and protect the lubricant in order to extend the life of chain coupling.

Chain couplings are offered in the industrys largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

The chain coupling has the advantages of simple structure (consisting of 4 parts), convenient installation and disassembly, 2 shafts which are joined without moving during disassembly, compact size, light weight, compensation ability, low installation accuracy, reliable operation, long life and low cost.

| Packing&Shipping | |

| Package | Standard suitable package / Pallet or container. Polybag inside export carton outside, blister and Tape and reel package available. If customers have specific requirements for the packaging, we will gladly accommodate. |

| Shipping |

10-20working days ofter payment receipt comfirmed (based on actual quantity). Professional goods shipping forward. |

About MIGHTY

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than 70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in time.

-Strick quality control are apply in the whole production.

we have incoming inspection,process inspection and final production inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export. MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from CHINAMFG customers in international sales.

FAQ

Q: Are you manufacturer or trading company?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Finding Reputable Suppliers or Manufacturers of Roller Chain Couplings

When looking for reputable suppliers or manufacturers of roller chain couplings for your specific power transmission needs, consider the following options:

- Industrial Trade Shows: Attend industrial trade shows and exhibitions related to power transmission and machinery. These events often feature leading manufacturers and suppliers showcasing their products.

- Online Directories: Utilize online directories and platforms that list suppliers and manufacturers of industrial equipment. Look for well-established companies with positive customer reviews and ratings.

- Industry Associations: Contact industry associations related to power transmission or mechanical engineering. They can provide recommendations for reliable coupling manufacturers and suppliers.

- Referrals and Recommendations: Ask for referrals and recommendations from colleagues, industry experts, or other businesses using similar equipment. Word-of-mouth recommendations can help you find trusted suppliers.

- Supplier Websites: Visit the websites of potential suppliers to learn more about their product offerings, certifications, and customer support services.

- Customer Support: Look for manufacturers or suppliers with excellent customer support to assist with technical inquiries, product selection, and after-sales service.

- Customization: If you have unique requirements, consider working with a manufacturer that offers customization options to tailor the coupling to your specific needs.

By researching and comparing different suppliers, you can find a reputable and reliable source for roller chain couplings that meets your power transmission needs.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

How to Select the Right Roller Chain Coupling for Specific Machinery or Equipment?

Selecting the right roller chain coupling for specific machinery or equipment involves considering several important factors. Here’s a step-by-step guide:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the driving and driven shafts. This will help you choose a coupling with the appropriate torque capacity for your application.

- Speed: Consider the operating speed of the machinery. Higher speeds may require special high-speed roller chain couplings designed to handle the centrifugal forces.

- Misalignment: Evaluate the degree of misalignment between the shafts. Different roller chain couplings have varying misalignment capabilities, so choose one that can accommodate the misalignment in your application.

- Space Constraints: Measure the available space for the coupling. Some roller chain couplings are compact and may be suitable for applications with limited space.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose a coupling material and finish that can withstand the environmental conditions.

- Load Characteristics: Assess the nature of the loads and any shock or vibration present in the system. For heavy-duty or shock-loaded applications, consider using heavy-duty roller chain couplings.

- Alignment Maintenance: Evaluate the ease of alignment maintenance. Some couplings may require more frequent checks and adjustments to maintain proper alignment.

- Backlash: Determine the level of backlash permissible in the application. Certain couplings may introduce minimal backlash, which is critical in precision systems.

- Cost: Consider the overall cost, including the initial purchase price and long-term maintenance expenses. Opt for a roller chain coupling that provides the best value for your specific needs.

By carefully considering these factors, engineers and designers can identify the most suitable roller chain coupling that ensures reliable and efficient power transmission for their machinery or equipment.

editor by CX 2024-01-10