Product Description

Product Description

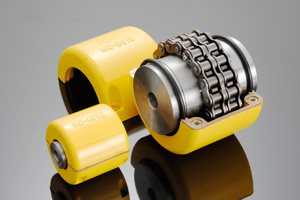

KC Type Spline Shaft Couplings Roller Chain Coupling

Product Features:

|

Product name |

Internal gear roller chain coupling |

|

Model |

KC chain coupling |

|

Inner diameter |

10-150mm |

|

Outer diameter |

75-355mm |

|

Thickness |

80-261mm |

|

Weight |

1.1-74.1kg |

|

Torque capacity |

40-25, ZheJiang , P.R. China /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial ConveyorsYes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems. The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads. Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation. When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Materials Used in Manufacturing Roller Chain CouplingsRoller chain couplings are typically constructed from high-quality materials to ensure durability and reliable performance. The most common materials used in their manufacturing include:

When selecting a roller chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, environment, and potential exposure to corrosive substances. Choosing the right material ensures the coupling’s longevity and efficient power transmission in the intended operating conditions.

Working Principle of Roller Chain Coupling and Its AdvantagesA roller chain coupling works on the principle of transferring torque between two shafts using a roller chain wrapped around sprockets on each shaft. The sprockets are connected by the roller chain, and when one sprocket rotates, it drives the other sprocket, transmitting the torque from one shaft to the other. The advantages of roller chain couplings over other coupling types include:

Overall, the working principle and advantages of roller chain couplings make them a popular choice for transmitting torque between shafts in diverse industrial applications.

Tags: chain | chain coupling | chain couplings | chain roller | chain roller chain | china chain | china coupling | china couplings | china roller chain | coupling | coupling chain | coupling shaft | couplings | couplings chain | couplings shaft | roller chain | roller chain chain | roller chain coupling | roller chain couplings | roller chain shaft coupling | roller chain type | roller shaft | shaft | shaft coupling | shaft couplings | shaft roller | spline coupling | spline couplings | spline shaft | spline shaft coupling | spline shaft couplings

|