Product Description

FAQ

Q:Is your company a trading company or a manufacturer?

A: We have our own factory.

Q:How long does the lead time take?

A: If the goods are in stock, it is generally 1-2 days; if the goods are not in stock, it is 5-10 days, depending on the quantity.

Q: Can I order shaft bore couplings that are not listed in the catalog?)(Additional machining service for coupling shaft hole

A:Of course.In addition, the recommended dimensional tolerance for the applicable shaft diameter is H7.

Q: How to handle when the received parts are of poor quality?

A:If there is any non-conformity of the product, please contact us immediately, we will check the problem in the first time, and rework or repair.

Q: Why choose XingHe Precision Transmission ?

A:As a professional manufacturer of coupling , we possess a skillful team of workers and designers To provide our customers with first-class services.

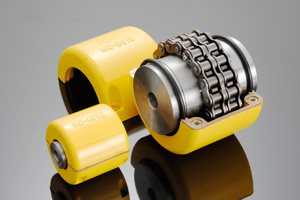

Comparison of Roller Chain Couplings to Other Coupling Types

Roller chain couplings offer distinct advantages and characteristics that set them apart from other coupling types, such as gear or disc couplings. Below is a comparison of roller chain couplings with these two commonly used coupling types:

- Roller Chain Couplings:

– Roller chain couplings are flexible and can accommodate misalignments, making them ideal for applications where shafts may not be perfectly aligned.

– They offer good shock absorption, which is beneficial in systems with varying loads or frequent starts and stops.

– Roller chain couplings are relatively compact and lightweight compared to other couplings, making them suitable for space-constrained installations.

– These couplings are cost-effective and provide a reliable and efficient power transmission solution.

- Gear Couplings:

– Gear couplings are capable of handling high torque and can transmit power efficiently, making them suitable for heavy-duty applications.

– They have a high level of torsional rigidity, ensuring accurate torque transmission without backlash.

– Gear couplings are generally more expensive than roller chain couplings.

– They require accurate alignment during installation, which can be challenging in some applications.

- Disc Couplings:

– Disc couplings offer high torque capacity and torsional stiffness, providing precise torque transmission and no backlash.

– They have a compact design and are often used in applications with limited space.

– Disc couplings can handle misalignment to some extent but may not be as forgiving as roller chain couplings.

– They are generally more expensive than roller chain couplings.

When choosing the appropriate coupling type, it is essential to consider the specific requirements of the application, such as torque, misalignment, speed, space limitations, and budget constraints. Each coupling type has its strengths, and the selection should be based on the demands of the mechanical power transmission system.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

How to Select the Right Roller Chain Coupling for Specific Machinery or Equipment?

Selecting the right roller chain coupling for specific machinery or equipment involves considering several important factors. Here’s a step-by-step guide:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the driving and driven shafts. This will help you choose a coupling with the appropriate torque capacity for your application.

- Speed: Consider the operating speed of the machinery. Higher speeds may require special high-speed roller chain couplings designed to handle the centrifugal forces.

- Misalignment: Evaluate the degree of misalignment between the shafts. Different roller chain couplings have varying misalignment capabilities, so choose one that can accommodate the misalignment in your application.

- Space Constraints: Measure the available space for the coupling. Some roller chain couplings are compact and may be suitable for applications with limited space.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose a coupling material and finish that can withstand the environmental conditions.

- Load Characteristics: Assess the nature of the loads and any shock or vibration present in the system. For heavy-duty or shock-loaded applications, consider using heavy-duty roller chain couplings.

- Alignment Maintenance: Evaluate the ease of alignment maintenance. Some couplings may require more frequent checks and adjustments to maintain proper alignment.

- Backlash: Determine the level of backlash permissible in the application. Certain couplings may introduce minimal backlash, which is critical in precision systems.

- Cost: Consider the overall cost, including the initial purchase price and long-term maintenance expenses. Opt for a roller chain coupling that provides the best value for your specific needs.

By carefully considering these factors, engineers and designers can identify the most suitable roller chain coupling that ensures reliable and efficient power transmission for their machinery or equipment.

editor by CX 2023-09-21